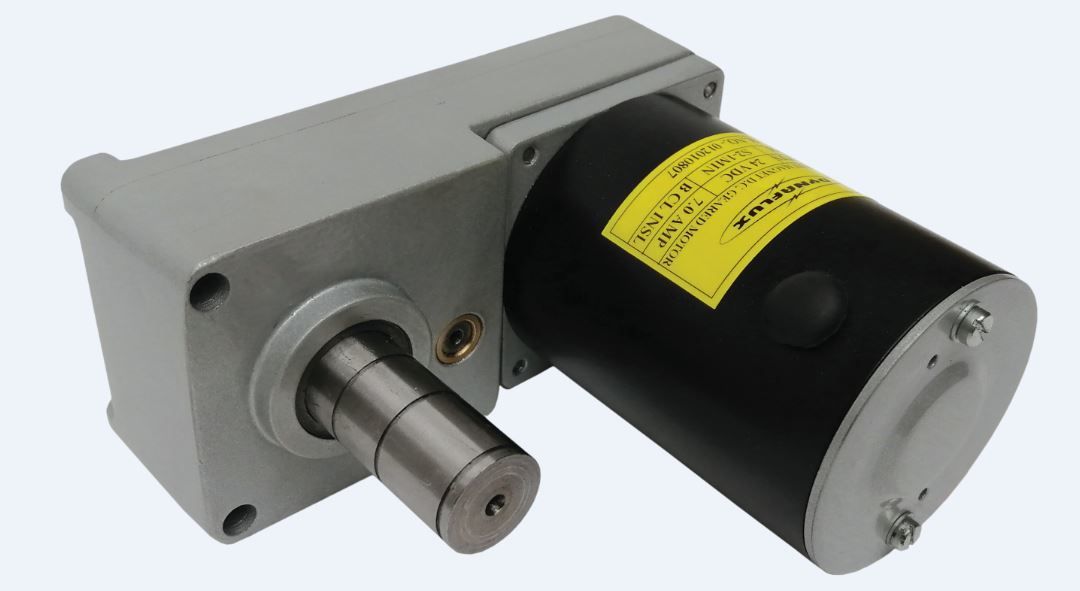

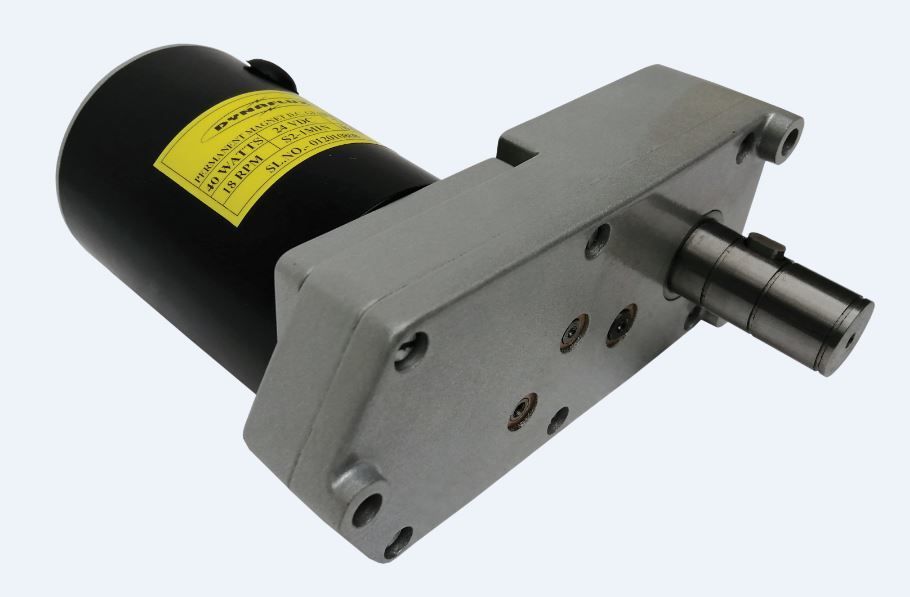

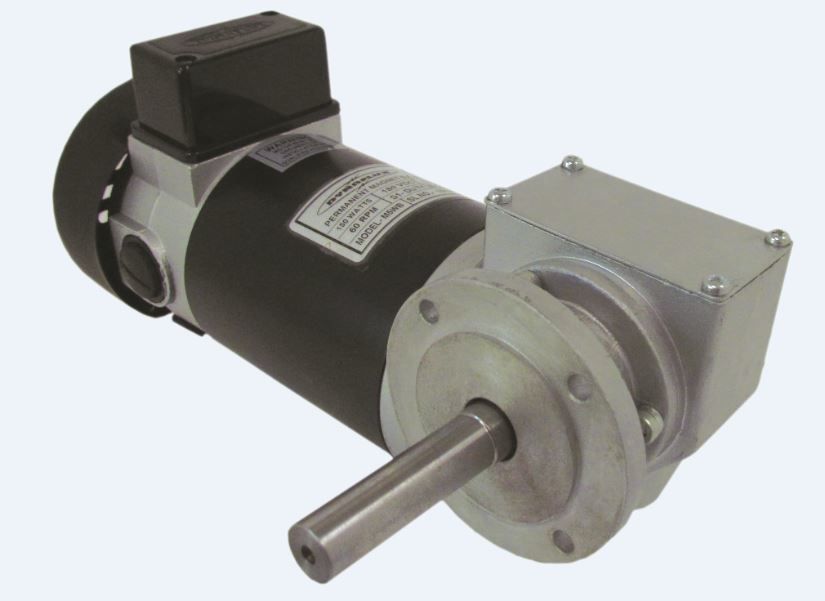

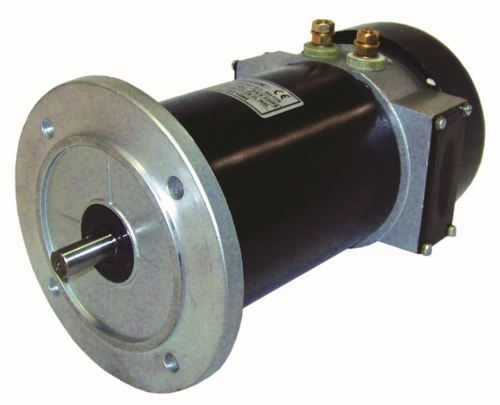

Worm Gear PMDC Motor

Price 15000 INR/ Buckle

Worm Gear PMDC Motor Specification

- Poles Number

- 4, 6

- Product Type

- Asynchronous Motor

- Protect Feature

- Drip-Proof

- Phase

- Single Phase

- Efficacy

- IE4

- Starting Type

- Electric Start

- IP Rating

- Ip21

Worm Gear PMDC Motor Trade Information

- Minimum Order Quantity

- 1 Container

- Payment Terms

- Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Worm Gear PMDC Motor

Worm Gear PMDC Motor

Transmit rotation between the perpendicular shaft (not intersecting, there is an offset between them). The worm resembles a screw which can be right handed or left handed. Worm gear sets usually used when high reduction in speed is desired. It transmits rotation from the worm to the worm gear, but not the opposite. Range from 20 Watt to 3 HP.

-

This motor uses permanent magnets in the stator to create the magnetic field, replacing stator windings.

-

This component consists of a screw-like worm that drives a mating spur or helical worm gear. The worm is typically a right or left-handed screw.

- The worm, driven by the PMDC motor, rotates.

- The worm meshes with the worm gear, transmitting rotation.

- The worm gear is designed to provide a significant reduction in speed and a substantial increase in torque at the output shaft.

- High Reduction Ratios: Worm gearboxes excel at achieving high reductions in speed.

- High Torque: They are ideal for applications requiring high output torque.

- Self-Locking: In many cases, worm gears are self-locking, meaning the gearbox will not turn backward from the output side, providing mechanical braking.

- Compact Design: Worm gearboxes offer a compact solution for high reduction ratios.

- Low Audible Noise: They are known for their low noise operation.

- High Radial Load Capacity: These motors can withstand high radial loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial PMDC Motor Category

Foot Mount PMDC Motor

Minimum Order Quantity : 1 Box

IP Rating : Other, IP54

Poles Number : 4

Shaft Diameter : 14 mm

Output Power : 250 W

Sealed Type : Other, IP54

Inline Geared Motor

Minimum Order Quantity : VARIABLE Box

IP Rating : Other, IP55

Poles Number : Other, 2 / 4 / 6 poles

Shaft Diameter : 18 mm 40 mm

Output Power : 0.18 kW 7.5 kW

Sealed Type : Other, IP55

Techno Generator

Minimum Order Quantity : VARIABLE Box

IP Rating : ip23

Poles Number : 4

Shaft Diameter : 38 mm

Output Power : 15 kVA

Sealed Type : Other, Enclosed

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS