Sdp Drive

Sdp Drive Specification

- Rated Voltage

- 415V

- Voltage

- 415V

- Horse Power

- 0.5 HP to 100 HP

- Noise Level

- Low

- Standard

- IS, IEC Certified

- Motor Type

- Induction Motor Compatible

- Features

- Compact Design, Robust Construction, Energy Efficient

- Power Rating

- As per model

- Torque

- High Starting Torque

- Bearing Type

- Deep Groove Ball Bearing

- Efficacy

- High

- Rated Frequency

- 50/60 Hz

- Ambient Temperature

- -10C to +50C

- Current Type

- AC

- Pressure

- Atmospheric

- Cooling Method

- Air Cooled

- Poles Number

- 2, 4, 6 Poles

- Starting Type

- Direct On Line (DOL)

- Sealed Type

- IP Protected

- Product Type

- Electric Drive

- Output Power

- SDP Drive

- Frequency (MHz)

- 50-60

- Protect Feature

- Overload, Short Circuit Protection

- Phase

- Three Phase

- Speed

- Variable

- Power

- 0.5 HP to 100 HP

- Color

- Blue

- Dimension (L*W*H)

- Standard, Customizable

- Weight

- Depends on model

- Shaft Diameter

- Customizable

- Mounting Type

- Base Mounted/Flanged

- IP Rating

- IP54/IP55

- Communication Port

- RS485/Modbus

- Braking Unit

- Built-in (for selected models)

- Digital Output

- Relay Output Provided

- Control Method

- Vector Control / V/F Control

- Environmental Protection

- Corrosion Resistant Paint

- Enclosure Type

- TEFC (Totally Enclosed Fan Cooled)

- Display Type

- Digital/LED

- Analog Input

- 4-20mA/0-10V

- Alarm Function

- Overvoltage, Undervoltage, Overtemperature

- Service Support

- Available across India

- Input Phase

- 3 Phase/1 Phase (as per model)

- Installation Site

- Indoor/Outdoor

- Operating Humidity

- 95% RH (Non-condensing)

- Programming

- User Friendly Parameter Setting

- Application

- Pumps, Fans, Conveyors, HVAC, Machine Tools

Sdp Drive Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia

About Sdp Drive

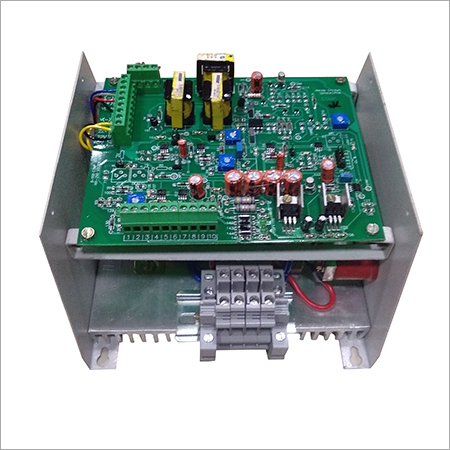

Weare, involved in manufacturing and supplying optimum grade SDPDrive. Offered machine is well suited to be used in control speed of DC motors up to 7.5HP . At ultra-modern production unit, this drive is made using best quality components. In addition to this, provided SDP Drive is tested on various parameters for ensuring flawless delivery to clients. We manufacture the range between 1hp-7.5 hp including power module with acc deacctime,techo feedback or volt feed back, current limiting.

Key Points:

- Less noisy working

- Robust construction

- Hassle free functionality

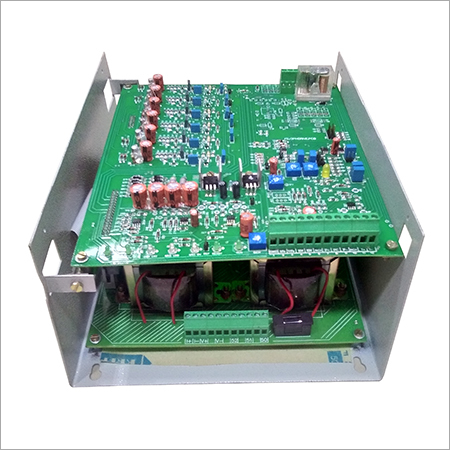

Cutting-Edge Control and Flexibility

Designed to enhance industrial automation, the SDP Drive offers Vector Control and V/F Control for precise speed regulation. With high starting torque and variable speed settings, you can optimize performance for induction motors in a range of demanding environments. Its adaptable input phases and digital or LED display enable seamless integration into new or existing systems.

Durability and Protection for All Conditions

Engineered for reliability, the drive features corrosion-resistant paint, TEFC enclosure, IP54/IP55 rating, and operates in ambient temperatures from -10C to +50C and humidity up to 95% RH. This makes it suitable for both indoor and outdoor installations, even in harsh industrial settings. The built-in alarm system ensures proactive protection against electrical faults.

Easy Programming and Service Support

The SDP Drive is designed for user-friendly parameter setting, allowing quick installation and configuration. Comprehensive service support is available across India, ensuring your operations remain smooth and efficient. Features like Modbus communication provide easy remote control and monitoring solutions for industrial applications.

FAQs of Sdp Drive:

Q: How can I select the appropriate model of SDP Drive for my application?

A: To choose the right SDP Drive, consider your input phase (single or three-phase), required power output (from 0.5 HP to 100 HP), motor compatibility, installation site (indoor or outdoor), and specific control method (Vector Control or V/F Control). Review your applications operational demands (such as torque and speed) to ensure the model matches your needs. Our team can assist in matching the best model for your equipment.Q: What are the main benefits of using the SDP Drive in industrial setups?

A: The SDP Drive offers high efficiency, robust construction, energy savings, and reliable protection for motors. Its advanced control methods, broad power range, and built-in protection features reduce downtime and maintenance costs while optimizing performance for pumps, fans, conveyors, HVAC, and more.Q: Where can the SDP Drive be installed, and what environmental conditions is it suitable for?

A: You can install the SDP Drive in both indoor and outdoor settings, thanks to its corrosion-resistant paint, TEFC enclosure, IP54/IP55 rating, and tolerance for ambient temperatures from -10C to +50C with up to 95% non-condensing humidity. This flexibility enables use in harsh industrial environments.Q: What is the process for programming and commissioning the SDP Drive?

A: Programming the SDP Drive is simple with its user-friendly parameter setting interface. After installation, you can quickly configure operational settings such as speed, torque, alarms, and communication using the digital or LED display. Comprehensive manuals and technical support are available for guidance.Q: How does the alarm and protection system of the SDP Drive enhance operational safety?

A: The SDP Drive is equipped with alarms for overvoltage, undervoltage, overtemperature, overload, and short circuits. These features provide real-time fault detection, safeguarding equipment and minimizing unplanned downtime, ensuring safer and smoother operation.Q: What are the available communication and monitoring options?

A: The SDP Drive features an RS485/Modbus communication port, supporting remote monitoring, control, and integration with automation or SCADA systems. This allows users to adjust parameters and track performance from a central location, enhancing operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DC Drive Category

Tpc Drive

Product Type : Other, TPC Drive

IP Rating : Other, IP55

Starting Type : Direct On Line

Poles Number : 2

Quater Hp Drive

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other

IP Rating : ip44

Starting Type : Direct On Line (DOL)

Poles Number : 4

One hp Drive ( model 1) SCR Based

Price 15000 INR / Billions Of Unit

Minimum Order Quantity : 1 Billions Of Unit

Product Type : Asynchronous Motor

IP Rating : Ip21

Starting Type : Electric Start

Poles Number : 4, 6

One Hp Drive Model 2 IGBT Based

Price 5000 INR / Bale

Minimum Order Quantity : 1 Number

IP Rating : Ip21

Poles Number : 4, 6

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS